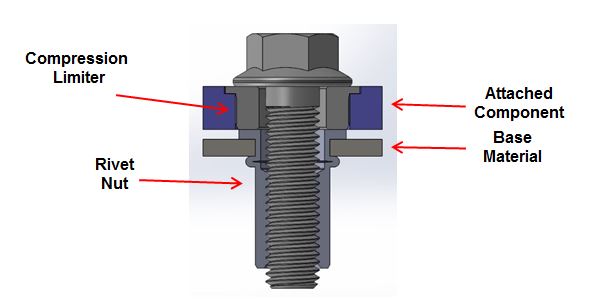

Compression limiters are cylindrical components, typically made from materials like steel, stainless steel, brass, or aluminum, designed to protect plastic or composite materials and fasteners from excessive stress during installation. These limiters help maintain the clamp load of the fastener, preventing deformation or damage to the surrounding material. They can be integrated into fasteners, such as rivet nuts, to facilitate metal-to-metal force transfer during joint assembly. This ensures that the adjacent materials remain intact and undamaged even under heavy loads. Compression limiters essentially act as spacers or shims that fill gaps to enable a stable metal-to-metal load transfer without distorting the base material. When the fastener, whether it’s a screw or bolt, is tightened, the compression limiter compresses between the fastener head and the joined metal parts, creating a compact and secure assembly. The design possibilities for compression limiters are vast. They can vary significantly in size, ranging from very small to quite large, and their surfaces can feature knurls, wedges, or remain smooth like a simple cylindrical spacer. Despite their differences, one thing all compression limiters share is that they are unthreaded. While a bolt might pass through them, these limiters do not have threads to hold the bolt in place. What Applications Do Compression Limiters Serve? Metal compression limiters find widespread use across various industries, including automotive, aerospace, construction, and agricultural equipment manufacturing. They are particularly valuable in situations where joints need to bear significant loads or stresses, such as structural connections or engine components. Their primary purpose is to avoid overloading or distressing the base material. How Are Compression Limiters Manufactured? These components are either cold-formed or machined based on specific requirements. Engineers at Sherex specialize in designing compression limiters tailored to particular applications, meaning many of these parts are custom-made for specific projects. Every year, Sherex produces hundreds of thousands of compression limiters at its Akron, Ohio facility. If you’re interested in learning more about compression limiters or need one for your application, feel free to reach out to us! Applications and Benefits In addition to reducing stress on base materials, compression limiters enhance the overall performance and durability of assemblies. For instance, in automotive manufacturing, they ensure critical components like engine mounts and chassis parts remain secure under dynamic conditions. Similarly, in aerospace engineering, they play an essential role in maintaining integrity in high-stress environments like landing gear systems. Whether you’re building heavy machinery or fine-tuning delicate instruments, compression limiters offer a reliable solution to ensure long-term functionality and safety. If you’re considering incorporating compression limiters into your next project, don’t hesitate to consult with experts who can guide you through selecting the right type for your needs. For further inquiries or to request samples, visit our website or drop us an email. We’d love to assist you in optimizing your designs with precision-engineered components! Diesel generator set is a kind of energy conversion equipment, which is converted from chemical energy to thermal energy and then converted into mechanical energy and finally converted into the required electrical energy, fuel oil is its raw material, and electric energy is its product. Diesel Generators,Engine Diesel Generator,2-25KVA diesel generator set Vibropac Machinery Co.,Ltd , https://www.vibropac-power.com

Diesel generator set is a kind of mechatronics equipment, which is composed of three major components: Diesel Engine, alternator and control system, and its technology involves various fields such as mechanical dynamics, electricity and automatic control.

Diesel generator set is a complete set of equipment, which is composed of some independent components, and the quality and performance of these independent components have an important impact on the quality of the whole system. Standby power is also called emergency power. The main purpose is that some units already have a stable power supply, but in order to prevent unexpected situations, such as circuit failures or temporary power outages due to force majeure, etc., they are still equipped with their own power supply for emergency power generation. The use units include: telecommunications industry, banks, airports, command centers, data centers, highways, high-grade hotels, office buildings, hospitals, etc

```html

```