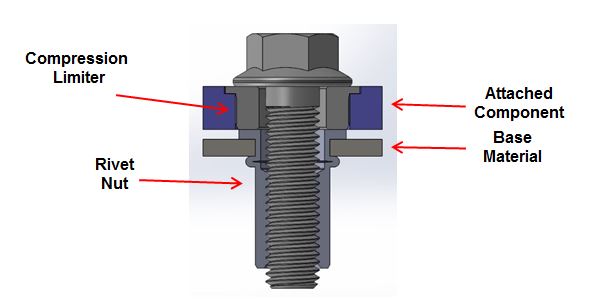

Compression limiters are cylindrical components made from materials such as steel, stainless steel, brass, or aluminum. Their purpose is to prevent overloading of plastic or composite materials and avoid loss of clamp load during fastener installation. These limiters can be integrated with fasteners, like rivet nuts, to ensure proper metal-to-metal force transfer during the assembly process. This helps protect the surrounding material from deformation or damage. Essentially, the compression limiter fills a gap in metal-to-metal load transfer without causing distortion to the base material. When a fastener, such as a screw or bolt, is tightened, the compression limiter gets compressed between the fastener head and the joined metal parts, creating a compact and secure assembly. The design possibilities for compression limiters are endless. They can vary greatly in size—ranging from very small to quite large—and may feature knurls or wedges, or simply resemble a smooth cylindrical spacer. One key characteristic shared by all compression limiters is that they are unthreaded. In some cases, a bolt might pass through the limiter, but it does not thread into the limiter itself, which means the bolt relies on external mechanisms for retention. What Applications Use Compression Limiters? Compression limiters made of metal are widely used across industries such as automotive, aerospace, construction, and agriculture, as well as in general building projects where high strength and reliability are essential. They are frequently employed in situations where joints need to endure significant loads or stress, such as structural connections or engine components. Their primary function is to minimize stress on the underlying material. How Are They Manufactured? Compression limiters are produced using either cold forming or machining techniques. Engineers at Sherex design these limiters specifically for particular applications, meaning many of these components are tailored to meet the requirements of individual projects. Each year, Sherex manufactures hundreds of thousands of compression limiters at its Akron, Ohio facility. If you're interested in learning more about compression limiters or need one for your specific application, feel free to reach out to us! Applications of Compression Limiters Compression limiters find their way into various critical applications due to their ability to distribute load effectively without damaging softer materials. For instance, in the automotive industry, they are used in suspension systems and other areas where precise load distribution is necessary. In aerospace, they support fasteners in critical structural joints, ensuring long-term durability under extreme conditions. Similarly, in construction, they help maintain integrity in heavy-duty structures, preventing damage to concrete or other base materials. Manufacturing Process The manufacturing process for compression limiters involves careful engineering to ensure precision and performance. Cold forming is often preferred for mass production because it maintains material properties while reducing costs. On the other hand, machining allows for greater customization, enabling manufacturers to create unique shapes and sizes tailored to specific needs. At Sherex, each compression limiter undergoes rigorous quality checks to guarantee consistency and reliability. Despite their relatively simple appearance, compression limiters play an indispensable role in modern engineering. Whether you're working on a cutting-edge aircraft or constructing a robust bridge, these components contribute significantly to the overall success of your project. If you require further information or assistance in selecting the right compression limiter for your needs, don't hesitate to contact us. Our team is here to support you every step of the way! In conclusion, compression limiters represent a vital component in many industries where reliability and strength are paramount. By understanding their design, functionality, and application, engineers can make informed decisions that enhance the performance and longevity of their projects. As technology continues to evolve, the importance of reliable fastening solutions like compression limiters will only grow stronger. Vibrating ruler or surface finishing screed is a commonly used tool in construction machinery, mainly used to remove air from concrete in construction, scrape the concrete floor, and increase the density and viscosity of concrete. Vibratory rulers are used in a wide range of applications. The vibrating ruler, also known as the walk-behind vibrating ruler, can be divided into gasoline vibrating ruler and electric vibrating ruler according to power. Generally, a vibration ruler of about 2 meters is used the most. Screed Vibrating Machine,Concrete Road Paving Leveling,Concrete Paver Leveling Vibropac Machinery Co.,Ltd , https://www.vibropac-power.com